Dual Flywheel Problems

It is recommended by many technicians that dual mass flywheels are replaced at every clutch change.

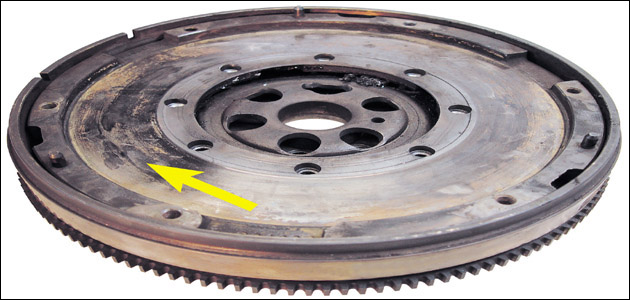

Dual flywheel problems. Intended to absorb stresses from the engine and transmission they can fail prematurely causing a metallic clanking sound andor vibration to be felt at certain engine speeds. This can be attributed to a bad flywheel which causes plate grinding amplified friction and oil contamination. Deutsche auto parts 5793 views. 1213pm bst 30 mar 2012.

Replacing a dual mass flywheel vs converting to a single mass flywheel. Problems of the dual mass flywheel this is a genius solution from the engineering point of view. Askdap episode 129 dual vs single mass flywheel duration. However in the regular exploitation of the car especially in its later life after about 200000 km the situation is not so shiny.

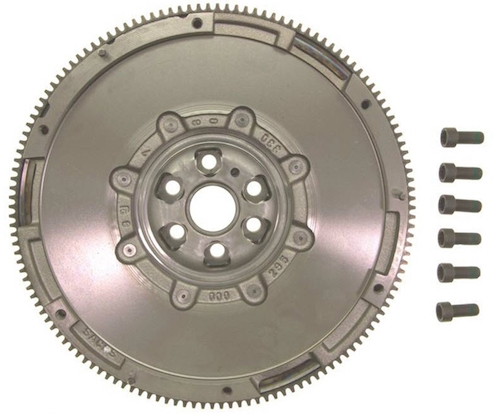

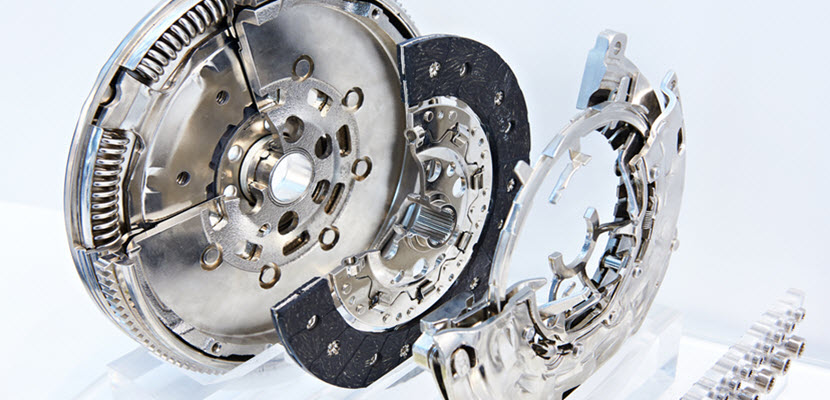

A smaller diameter flywheel bolts to the engine and sits inside of a drum brake like outer flywheel. When these things happen the inner machinery of the flywheel is prone to gear slippage. This design offers a bit of buffering between the engine and transmission to enhance smoothness during clutch engagement. How to prevent dual mass flywheel problems honest john offers some tips on how to make dual mass flywheels last as long as possible.

On the plus side dual mass flywheels reduce the torsional vibrations in the driveline and the other related vibration and noises. In situations where the engine torque is intermittent the flywheel will supplement this with its own stored rotational energy. Dual mass flywheel problems. On the negative side.

A sectioned dual mass flywheel. Dual mass flywheel failures are a common problem in vag diesels unfortunately. The smaller flywheel engages the larger one via a set of springs. A soft pedal andor delay in engagement after the clutch releases are the most recognizable signs of gear slippage.