Best Way To Clean Engine Block Surface

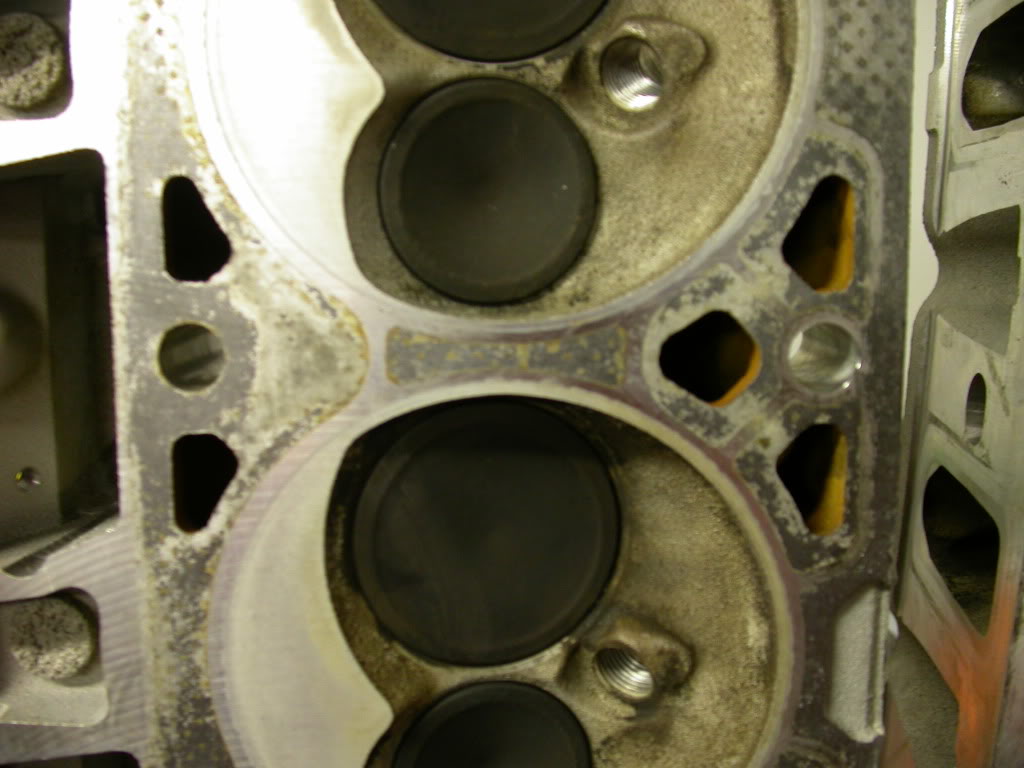

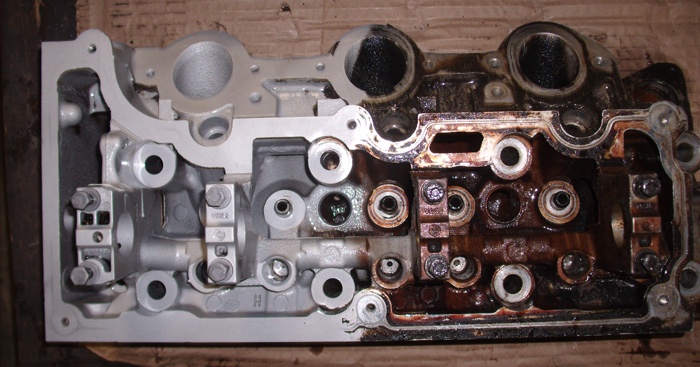

Obviously the process you choose to clean blocks and heads must be effective at removing dirt grease oil paint carbon rust and scale from internal as well as external surfaces.

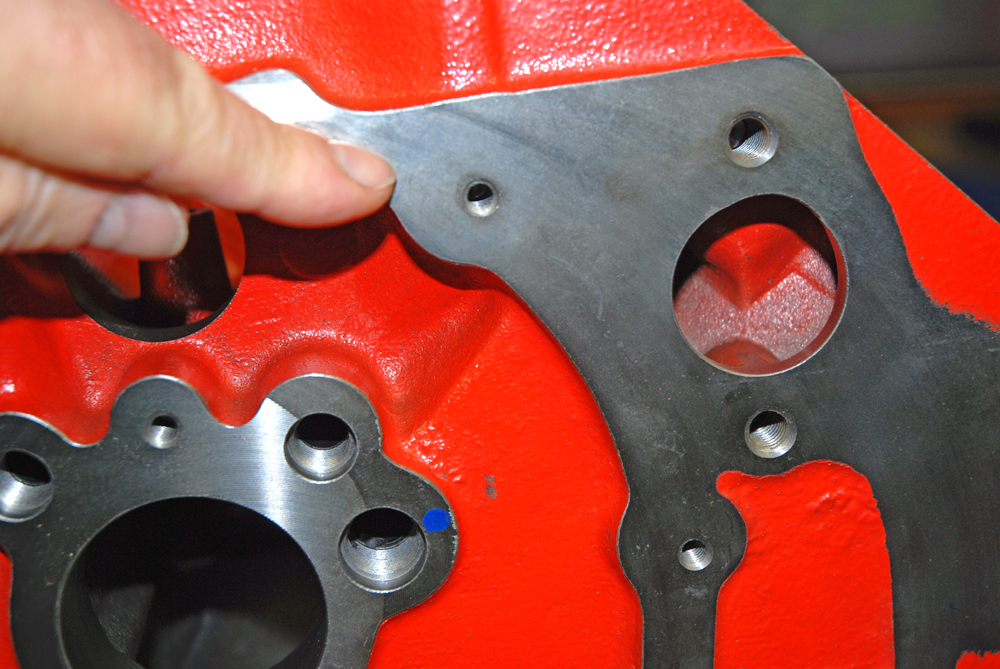

Best way to clean engine block surface. I understand the 3m roloc discs are recommended for surface prep also. Aluminum head should be as smooth as possible to allow sliding on the gasket as it will expand faster and farther than cast iron. The block prep kit contains two different types of them. I am using a fel pro mls gasket and research says no sealant should be used on this gasket.

The medium grade discs are for iron blocks and the very fine grade discs are for aluminum blocks. Step in block preparation is to clean those surfaces with a standard abrasives general purpose surface conditioning disc. Choosing a cleaning process. Fill the hopper on your media blaster with media.

Use a media blaster to remove loosened paint. Disconnect the grinder install the standard abrasives quick connect 2. As long as there are no nicks or burs on the block you are good to reassemble clean with brake cleaner and red scotch bright. Even then you need an oil free clean surface for the paint to stick.

My best method for cleaning head gasket other engine surfaces. Cylinder walls and block deck duration. Engine block surface is pretty typical needs some smoothing and cleaning. Clean same as block.

How to super clean your engine bay duration. For paint to adhere to your engine block for the long haul it needs to be cleaned of any paint that is currently loose or may come loose in the near future. He uses a long handle scraper tool with razor blades to clean off the surface. I have a very smooth clean head mating surface straight from the machine shop.