How Does A Torque Limiter Work

They protect a mechanism through various ways.

How does a torque limiter work. They are generally used to protect equipment from damage or mechanical overload although some varieties also protect the work upon which the mechanical device is working. They protect a mechanism through various ways. As the latch disengages it can also signal the machine controller of the overload condition and stop the machine. How do they work.

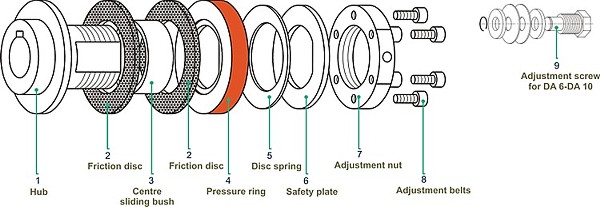

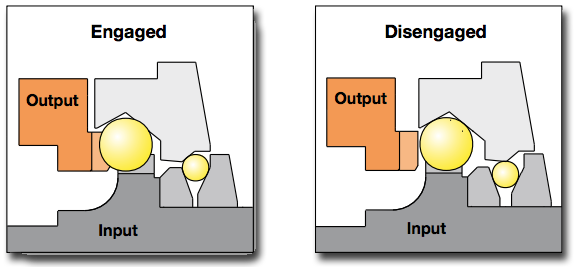

They protect the drive and driven components from damage in the event of a torque overload by slipping so that the amount of torque transmitted from one component to the other does not exceed the pre set amount. A torque limiter may limit the torque by slipping as in a friction plate slip clutch or uncouple the load entirely as in a shear pin. This type of torque limiter provides positive protection on the output side of the machine and is backlash free. The action of a torque limiter is especially useful to limit any damage due to crash stops and jams.

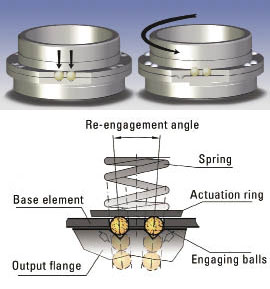

In essence they are used to shut down a machine and dissipate any rotational energy without causing damage to the machine. Other types of mechanical torque limiting devices rely on springs with special negative rate characteristics that work in unison with a torque transmission system of balls interfacing two indents. A torque limiter is an automatic device that protects mechanical equipment or its work from damage by mechanical overload. Here not as accurate as a torque wrench but better than just using an impact alone.

The most common types are shear pins slip clutches and balldetent torque limiters. Torque limiters protect equipment or loads from excessive torque. Mechanical friction torque limiter mach iii friction torque limiters are always engaged and transmit a fixed amount of torque from one component to another. What you need to know about mechanical torque limiters.

It is self actuating and the latch re couples in the same position thus preserving machine timing. Torque limiters are applied in various fields such as in manufacturing industries and transportation. One is by slipping while some completely uncouple the load at the first sign of overload or also known as disconnect type.