Cold Stitching Engine Blocks

It does change if exposed to high temperatures over long periods of time like exaust manifolds and wood burning stoves.

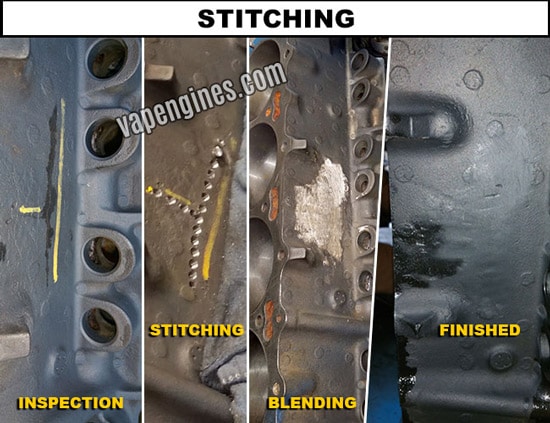

Cold stitching engine blocks. The other common attempt at fixing a cracked block is called cold metal stitching. From welding and brazing to cold metal stitching. Metal stitching crack repair of cast iron vintage 426 hemi block. The process is called graphitization.

Specializes in all aspects of the repair of cracked and damaged cast iron and other cast metals. Introduction to cracked engine block repair. Belzona offers a solution that does not require hot work or specialist tools. The block had suffered serve cracking due to freezing in the water jackets.

Stitchweld casting repairs ltd is well known for offering sound economical repairs to cracked or damaged cast iron including cylinder head and engine block repair. Cast iron can be welded using an arc welder with cast iron rod. An engine block is subject to drastic temperature changes. Keys made of a special material are inserted into the pockets and caulked into an interlocking form.

There are plenty of instances where perfectly goodand often rarecast iron cylinder head and engine block castings are scrapped due to the presence of a hairline crack in an external surface. Written by on january 26 2012. Often these fractures result after a freeze. So if the crack is cold metal stitched the crack will open and close with the changes in the temperature.

Step by step report presentation pdf 414 mb in this example of metal stitching a customer came to us for the repair on a vintage 426 hemi engine block. Cold metal stitching is used on cast iron components that arent subject to drastic temperature changes. Stop the crank in the engine block before a leakage causes disastrous and costly consequences. Metal stitching has become a generic phrase that describes a method of repairing cracks in cast metals without welding.

It is possible to weld cast iron using an arc welder and the proper welding rods but that often can cause deformation to your engine block or leave the welded area far more brittle and susceptible to further cracking. Pockets for the keys are produced at 90 degree angle to the crack in the predefined distances. The cracks can lead to a series of problems for that reason they need to be eliminated.